Understanding Your Tamobyke's Hydraulic Brake System

Your Tamobyke electric bike features advanced hydraulic disc brakes designed to handle the additional weight and speed of electric assistance. Hydraulic brakes have a hydraulic line filled with mineral oil running from the brake lever to the brake caliper. This closed-loop system provides superior modulation and stopping power compared to traditional cable-actuated brakes.

How Hydraulic Brakes Work on Electric Bikes

When you squeeze the brake lever on your Tamobyke, several components work together:

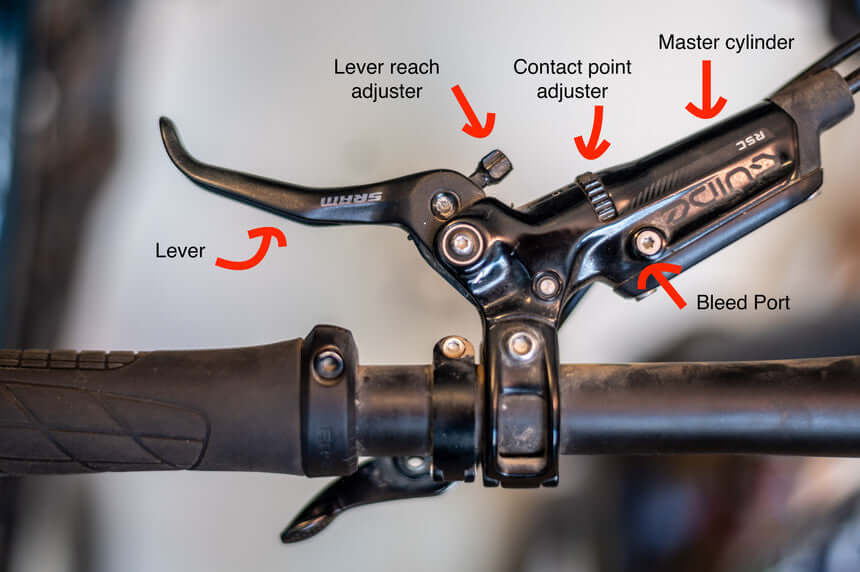

The Brake Lever Assembly: Contains a master cylinder with a piston that pressurizes the brake fluid when activated.

Hydraulic Line: Transfers pressurized fluid from the lever to the caliper, typically using mineral oil for optimal performance.

Brake Caliper: Houses pistons that push the brake pads against the rotor when fluid pressure increases.

Brake Pads and Rotor: Create friction to slow your electric bike, with specialized compounds designed for e-bike applications.

When to Bleed Your Tamobyke's Brakes

One of the most common issues e-bike riders run into is the need for a brake bleed. The telltale sign of needing a brake bleed is pressing on your brake and having it feel "squishy", "spongy", or not having it engage at all.

Warning Signs Your Brakes Need Attention

Spongy Lever Feel: If your brake lever travels further than normal before engaging, air may have entered the system.

Reduced Stopping Power: Noticeable decrease in braking effectiveness, especially important given your e-bike's higher speeds.

Lever Reaches Handlebar: If the lever pulls all the way to the grip without firm resistance, immediate attention is required.

Inconsistent Braking: Erratic brake performance or different feel between front and rear brakes.

Visual Contamination: Dirty or discolored brake fluid visible in the reservoir.

Why E-Bikes Need More Frequent Maintenance

Electric bikes like your Tamobyke face unique challenges:

- Increased Weight: Battery and motor systems add weight, requiring more braking force

- Higher Speeds: Electric assistance enables faster riding, generating more heat

- Extended Use: E-bikes encourage longer rides, increasing brake system stress

- Temperature Fluctuations: Using the electric bike brakes frequently while riding downhill can warm up this fluid especially at the caliper, and changes in weather can then make the hydraulic fluid colder or hotter while the e-bike is in storage.

Essential Tools and Materials

Required Equipment for Brake Bleeding

Brake Bleed Kit: Universal mineral oil kit compatible with most hydraulic systems, including:

- Two syringes (10-20ml capacity)

- Bleed tubing and fittings

- Bleed blocks or spacers

Quality Mineral Oil: The mineral oil used in brakes is a low viscosity refined petroleum oil, similar to industrial hydraulic fluids or automatic transmission fluid. Choose reputable brands like Shimano, Magura, or TRP.

Basic Tools:

- Hex keys (2mm, 2.5mm, 3mm)

- 7mm box wrench or ring spanner

- Torx keys (T15, T25)

- Cable ties and rags

Safety Equipment:

- Disposable gloves (nitrile recommended)

- Safety glasses

- Well-ventilated workspace

Choosing the Right Brake Fluid

It is crucial you use the fluid specified by your brake manufacturer. Failure to do so will result in premature brake failure. Most modern e-bike hydraulic systems, including those on Tamobyke models, use mineral oil rather than DOT fluid.

Mineral Oil Advantages:

- Non-corrosive to bike components and paint

- You can keep mineral oil on the shelf indefinitely, even if the seal is opened, and braking performance won't be decreased when it's used.

- Environmental safety

- Compatible with most e-bike brake systems

Pre-Bleeding Inspection and Preparation

Safety First: Bike Positioning

The first step in bleeding your brakes is to put your bike into a work stand. We will need to rotate the bike a bit, so being able to put your bike in a work stand is a must for this service.

Proper Bike Setup:

- Secure your Tamobyke in a quality work stand

- Ensure stability to prevent tipping during rotation

- Position the bike to access both front and rear brake systems

- Remove the battery if possible to reduce weight and improve balance

Initial System Assessment

Visual Inspection:

- Check brake fluid level in reservoir (if visible)

- Examine hydraulic lines for damage or kinks

- Inspect brake pads for wear and contamination

- Verify rotor condition and alignment

Functional Test:

- Squeeze it firmly—does it feel spongy or unresponsive? Weak brake response might mean low fluid pressure or air in the system.

- Test both front and rear brake levers

- Note any differences in feel or travel distance

Workspace Preparation

Brake fluid's messiness demands a spotless area, so grab cleaning supplies and handle debris removal like a pro. Workspace safety is non-negotiable, and a clean space prevents slipping tools or contamination during hydraulic brake bleeding.

Clean Environment Setup:

- Cover surrounding areas with protective materials

- Organize tools within easy reach

- Ensure adequate lighting for detailed work

- Have isopropyl alcohol ready for cleanup

Step-by-Step Brake Bleeding Process

Phase 1: System Preparation

1. Remove the Wheel Next, remove whoever wheel you are going to bleed the brake on. The fluids used in a bleed can contaminate the rotor, and we will need access to the brake caliper, so it is best to remove the wheel.

2. Position the Brake System With the wheel now removed, set the bike in a position that will put the braking system vertical. We want the air bubbles to travel upwards and out.

3. Remove and Secure Brake Pads After the brake lever has been rotated, remove the brake pads from the caliper and set them to the side (we do not want them anywhere near the bleeding process or tools).

4. Install Bleed Block Use your piston press to reset and push the pistons in the caliper. With the pistons pushed back in, you will install the bleed block.

Phase 2: Lever Preparation

1. Position Brake Lever It's really important to make sure the bleed port on your lever is the highest possible point, while the port on your caliper is the lowest point in the system when bleeding, otherwise bubbles will get trapped in the line.

2. Access Bleed Port

- Remove the bleed screw using appropriate hex key (typically 2.5mm)

- Keep the O-ring safe and clean

- Thread in funnel or syringe fitting

Phase 3: Caliper Setup

1. Locate Caliper Bleed Nipple

- Find the bleed valve on the brake caliper

- Use a wrench to loosen the bleeder valve on the brake caliper or wheel cylinder. This will allow the brake fluid to flow out of the system.

2. Prepare Bleeding Syringe Fill the syringe that will be going to your caliper with the mineral oil. Rotate the syringe upside down so all of the fluid goes to the bottom and then suck some more air in. Then, push all of the air out until the fluid just squirts out. We want no air bubbles in our line.

Phase 4: The Bleeding Process

1. Connect Systems

- Attach fluid-filled syringe to caliper bleed nipple

- Secure connection to prevent leaks

- Connect empty syringe or funnel to lever bleed port

2. Fluid Transfer Method With the bleeder valve open, have someone else pump the brake lever several times until you see air bubbles come out of the bleeder valve. Then have them hold the lever down.

3. Push-Through Technique

- Slowly push mineral oil from caliper syringe

- Watch for air bubbles at lever end

- Repeat steps 4-6 until there are no more air bubbles coming out of the brake line. Be sure to keep the brake fluid level in the reservoir topped up so that air does not get back into the system.

4. Bubble Elimination

- Make sure that when you start at the caliper, you tip it and flick it so the bubbles rise. Not just the brake line, but where the brake line attaches to the caliper. Tip the caliper upwards towards the brake line.

- Gently tap hydraulic lines to encourage bubble movement

- Continue until fluid runs clear without bubbles

Phase 5: System Completion

1. Close Bleed Valves While the lever is still held down, use the wrench to tighten the bleeder valve. Be careful not to over-tighten it, as this can damage the valve.

2. Final Fluid Level Check Once you are finished bleeding the brakes, check the brake fluid level in the reservoir and add more if necessary.

3. Reinstall Components

- Remove bleed block and reinstall brake pads

- Reinstall wheel with proper torque specifications

- Clean any spilled fluid with isopropyl alcohol

Testing and Fine-Tuning

Initial Function Test

Test the brakes by pumping the lever a few times and making sure they feel firm and responsive.

Lever Feel Assessment:

- Firm, consistent resistance throughout travel

- No spongy or mushy feeling

- Proper engagement point (not too close to grip)

- Equal feel between front and rear systems

Performance Verification

Static Testing:

- Pump brake lever 5-10 times

- Hold lever pressed for 30 seconds

- Lever should maintain position without sinking

- Release and repeat test

Dynamic Testing:

- Test ride in safe, controlled environment

- Progressive braking from low speeds

- Verify consistent stopping power

- Check for any unusual noises or vibrations

Brake Adjustment and Optimization

Lever Reach Adjustment: Most Tamobyke brake systems include reach adjustment:

- Locate reach adjustment screw (usually behind lever)

- Adjust to comfortable position for your hand size

- Ensure full braking power is still available

Pad Alignment Check:

- Verify pads contact rotor evenly

- Adjust caliper position if necessary

- Ensure no pad rub during wheel rotation

Maintenance Schedule and Best Practices

Recommended Service Intervals

Regular Inspection: Monthly visual checks of brake system Fluid Replacement: Depending on how often and how far you ride, you will need to bleed your Shimano hydraulic disc brakes about every six months. Complete System Service: Annually or every 2,000-3,000 miles

Factors Affecting Service Frequency

Heavy Use Indicators:

- Daily commuting on your T63

- Frequent mountain biking with V20 Pro

- Long-distance touring applications

- Riding in harsh weather conditions

Extended Intervals Possible:

- Occasional recreational riding

- Primarily flat terrain usage

- Garage-stored bike with stable temperatures

- High-quality mineral oil systems

Preventive Maintenance Tips

Protect Your Investment:

- Store your Tamobyke in temperature-controlled environment

- Avoid hanging bike by brake levers

- Regular cleaning around brake components

- Monitor brake pad wear closely

Early Problem Detection:

- Listen for unusual brake noises

- Feel for changes in lever action

- Watch for fluid leaks around fittings

- Monitor stopping distance consistency

Troubleshooting Common Issues

Persistent Spongy Feel

Possible Causes:

- Incomplete air removal from system

- Worn brake pads requiring replacement

- Damaged hydraulic seals

- Contaminated brake fluid

Solutions:

- Repeat bleeding process with emphasis on bubble removal

- Replace brake pads if worn beyond minimum thickness

- Inspect system for seal damage or leaks

- Perform complete fluid flush if contamination suspected

Brake Drag or Rubbing

Diagnostic Steps:

- Check wheel installation in dropouts

- Verify caliper alignment with rotor

- Inspect rotor for warping or damage

- Ensure proper pad retraction after bleeding

Reduced Stopping Power

Performance Analysis:

- Verify proper brake fluid type and quality

- Check brake pad compound compatibility

- Inspect rotor surface condition

- Confirm proper caliper piston function

Advanced Maintenance Considerations

Upgrading Your Brake System

While Tamobyke electric bikes come with quality hydraulic brakes, some riders may consider upgrades:

Performance Enhancements:

- Higher-capacity brake pads for extended riding

- Upgraded rotors for improved heat dissipation

- Performance brake fluids for extreme conditions

Compatibility Considerations:

- Maintain electrical brake cutoff functionality

- Ensure rotor size compatibility with frame clearances

- Verify mounting standards match your Tamobyke model

Seasonal Maintenance

Winter Preparation:

- More frequent inspection due to road salt exposure

- Consider winter-specific brake pad compounds

- Protect hydraulic lines from freeze-thaw cycles

Summer Readiness:

- Check brake cooling capacity for long descents

- Verify brake pad compound for high-temperature performance

- Ensure adequate ventilation around brake components

Safety Considerations and Professional Service

When to Seek Professional Help

Remember, bleeding hydraulic brakes can be a delicate process, and it is important to follow the manufacturer's instructions for your specific vehicle. If you are unsure about any aspect of the process, it is always best to consult a professional mechanic or refer to your vehicle's service manual.

Professional Service Recommended:

- First-time brake bleeding attempt

- Suspected hydraulic system damage

- Brake failure or complete loss of function

- Uncertainty about proper procedures

Safety Critical Reminders:

- Never ride with compromised brake function

- Test brakes thoroughly after any maintenance

- Keep spare brake pads available for emergencies

- Understand your local e-bike brake regulations

Legal and Warranty Considerations

Warranty Protection:

- Document all maintenance performed

- Use manufacturer-recommended fluids and procedures

- Keep receipts for parts and professional services

- Understand what maintenance is required vs. optional

Conclusion: Keeping Your Tamobyke Safe and Reliable

Proper hydraulic brake maintenance is essential for safe e-bike operation. Your Tamobyke's advanced braking system requires regular attention to perform optimally, especially given the unique demands of electric bike riding. Whether you're commuting daily or exploring new trails, maintaining your brake system ensures reliable stopping power when you need it most.

Regular brake bleeding, combined with proper inspection and timely component replacement, will keep your Tamobyke performing at its best. Remember that brake maintenance is a safety-critical task – when in doubt, consult with qualified professionals who understand electric bike systems.

For more information about hydraulic brake systems and the latest in bicycle brake technology, stay tuned to our upcoming posts covering brake pad selection, rotor maintenance, and winter brake care.

By maintaining your Tamobyke's hydraulic brakes properly, you're investing in both performance and safety – ensuring many miles of confident, controlled riding ahead.

Share:

How to Convert a Regular Bike to Electric: Complete DIY Conversion Guide

Tamobyke Brake Upgrade Guide: From Stock to Performance